The first snow of the year is one of those moments that you know you’re going to enjoy. The kids are finally home from school, and they’re happy as can be! This sounds great, but anyone with a driveway or patio knows how quickly ice and snow can build up on these surfaces in northern climates. So, what do you do when your pavement is at risk of damage due to heavy snow?

Protecting your patio and driveway from the cold can be a challenge. As we’ve seen in winter, snow and ice can make it difficult to shovel. Here are three ways to can protect our patios and driveways from the cold.

1) Remove Stills and Oil Stains

What can you do to protect your patio and driveway from the cold? Remove stills, oil stains, grease spills, or other contaminants. These will freeze during a frosty night and ultimately damage surfaces when they melt again in springtime.

Oil stains and grease spills can also cause your tires to skid when driving over them. Be sure to remove any stains before the weather gets too cold outside. If left to their elements, the untreated stains can wreak havoc on your pavement’s foundation, especially if they go through the freeze-thaw cycle.

2) Seal your Driveway

If you haven’t seal coated the driveway in the last two years or so, now is the time to think about it seriously! Sealing the driveway before the winter will not only make your driveway last longer but also protect it from freeze-thaw damage. Hire a professional contractor like Straight Edge Contractors for the best results.

A quality sealer will be impervious to water as compared to other coatings that are less durable. You’ll want to apply an additional layer of coating for maximum protection against ice formation on your driveway surface. This is especially important if there’s a good chance of an early frost before year-end.

3) Remember to Clear Snow During Winters

Once the winter sets in, you need to be on your toes at all times. Clear the accumulated snow as the weather settles and ensure your driveway is not inaccessible due to heaps of snow. Also, keep your sidewalk and patio free of any snow accumulation.

4) Clear All Patio Furniture and Accessories

Winter is not the time to hang out outdoors. So, bring all your patio furniture and accessories indoors. This will protect them from damage from the harsh winter elements. If you’ve got a central heating location customized to brave the winter season, you need to ensure the snow and the weather do not damage it!

Your concrete and asphalt surfaces are at risk during the winter season in El Paso. Take action now and call Straight Edge Contractors for a winter maintenance routine. We ensure that your pavement and patio are able to withstand the harsh cold, and customers can visit you without the risk of an accident. Get an estimate from our team now!

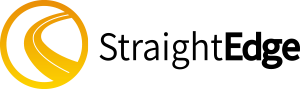

Asphalt is one of the most popular paving materials. It is durable, flexible, and long-lasting. Over time though, asphalt can develop cracks. You must seek immediate professional help to prevent further damage and keep your pavement looking its best.

If you think your asphalt driveway is beyond repair, you must think again! Contrary to popular belief, most driveways and parking lots can be saved with a little bit of TLC – namely, filling and sealing the cracks.

Let’s look at the details to understand the issue better.

Active and Passive Cracks:

There are two categories of cracks that commonly form in asphalt: active and passive.

Active asphalt cracks are also called live cracks. They expand in length, width, and depth over time. These cracks develop due to external forces, such as heavy vehicles or tree roots. These cracks can be difficult to repair due to their size. The leading cause is overloading and thermal expansion, e.g., cracks due to freeze-thaw.

On the other hand, passive cracks are caused by weathering or wear and tear. They tend to be smaller and easier to fix. By filling and sealing these cracks, you can prevent them from becoming active cracks.

Common Asphalt Cracks

Before we get into crack filling and sealing, let’s look at the most common types of cracks. It will help you better understand what kind of repair your asphalt needs.

The three most common types of asphalt cracks are:

Alligator Cracking: Also known as spider webbing, alligator cracks are characterized by a network of small cracks that branch out from the main crack. This type of damage is usually caused by poor drainage or too much traffic.

Block Cracking: Block cracking looks like a series of large, connected squares. It’s usually caused by shrinkage as the asphalt dries and cures.

Linear Cracking: Linear cracks are long, thin cracks that run in a straight line. They can be caused by temperature changes, heavy traffic, tree roots, and poor drainage.

Filling and Seal Coating Asphalt Cracks:

The best way to prevent damage from asphalt cracks is to fill and seal them as soon as they appear. Filling cracks with a sealant will help stop water from seeping into the crack, which can cause even more damage. Seal coating your pavement will also protect it from the sun’s ultraviolet rays, which can cause fading and cracking.

Is the Process Easy?

Filling and sealing asphalt cracks is easy and does not require special equipment or training. However, it is essential to choose a suitable sealant for the job. There are many different sealants on the market, so be sure to consult with a professional before purchasing.

Does Your Asphalt Pavement Require Maintenance?

Regular maintenance of your pavement will extend its life and keep it looking its best. Because of this, we recommend seal coating your pavement every two to three years. It will protect it from the elements and keep it looking new for years to come. Contact your local paving contractor to learn about asphalt crack repair solutions for your home.

Summing Up:

For over six years at Straight Edge Contractors LLC, we have been repairing and maintaining houses and businesses in El Paso, TX. Our unmatched asphalt crack repair and maintenance services will keep your property looking brand new for a long time.

Why Seal Coating Doesn’t Cure Properly

Sealcoating is an essential component of routine maintenance of asphalt driveways. It creates a barrier between the pavement surface and the factors that can damage it, like rain, snow, ice, and UV rays.

Several seal coat products are on the market, but not all work as advertised. In some cases, a seal coat will fail to cure correctly, leading to severe problems down the road. If you’re considering seal coating your driveway, it’s essential to research and find a product that will give you the best results.

This blog post by Straight Edge Contractors LLC discusses why a seal coat may not cure properly.

Common Mistakes:

The seal coating procedure demands patience and meticulousness. But even if you follow all the instructions to a T, things can still go wrong. Here are a few frequently made blunders by homeowners when applying a seal coat to their roadways:

- Applying the sealant too thick or too thin

- Not allowing enough time for the sealant to dry

- Seal coating in direct sunlight

The Required Time and Temperature:

A seal coat should be applied when the temperature is between 60 and 90 degrees Fahrenheit. If it’s too cold, the seal coat won’t cure properly. If it’s too hot, the seal coat will evaporate before it has a chance to cure.

Not only must the temperature be precise, but you must also allow enough time for the seal coating to dry. Depending on the product you use, this can take 24 hours to 72 hours.

If you don’t have time to wait around for the perfect weather conditions, there are products on the market that can be used in a broader range of temperatures. However, these products usually come with a shorter curing time, so you’ll need to be extra careful not to damage the seal coat while it’s still curing.

Why Doesn’t the Seal Coat Cure Properly?

An inadequately cured seal coat is more susceptible to damage and wear and tear. This means that it won’t be able to protect your asphalt, and it will need to be replaced more often.

Here are a few reasons why the seal coat might not cure properly:

Use of Substandard Material:

If you use a substandard material, it’s likely that the seal coat won’t cure properly. This is because the material might not be able to withstand the elements, or it might not be compatible with the asphalt. An example of a substandard material is using an asphalt emulsion with a low softening point.

Incorrect Storage of Material:

The right way to store the seal coat material is in a cool, dry place. If it’s stored in an area that’s too hot or too cold, it can affect the material’s ability to cure properly.

Improper Mixing:

Mixing is a significant part of the seal coating process, and if it’s not done correctly, the seal coat won’t cure properly. It is because the material needs to be mixed in the right proportions to be effective. The recommended ratio is two parts asphalt to one part sealer.

Inadequate Preparation of the Surface:

No amount of emphasis is less on the importance of preparing the surface before seal coating. If the surface isn’t prepped correctly, it can cause the seal coat not to adhere correctly, which will lead to premature failure.

Ending Note:

So, what can you do to make sure your seal coat cures properly? Start by hiring a reputable contractor, such as Straight Edge Contractors LLC in Midland, TX.

Seal coating is an integral part of keeping your asphalt in good condition, so don’t wait until it’s too late.

4 Lighter Alternatives To Using Concrete

Is there anything more burdensome than a concrete driveway or patio? It can be tough enough to lug a single bag of the concrete mix around, let alone try to maneuver a truck full of the stuff. And once it’s in place, you better hope your back is up for keeping it clean! There has to be a better way. So, are there lighter alternatives to concrete?

Yes, there are! For the past six years, Straight Edge Contractors LLC has transformed several residential and commercial properties with various products; therefore, we stand in a position to give an educated answer.

Why is a Lighter Alternative Important?

Lighter alternatives are essential because they provide an option that is less labor-intensive, easier to move and install, and much more lightweight. These alternatives can be used in various ways, including driveways, patios, steps, and walkways.

There are a few different types of lighter alternatives to concrete.

1. Straw Bale

Strawbale structures were prevalent until the industrial revolution when homes became primarily composed of manufactured and imported materials. They were employed for the inside of a frame, replacing natural and locally available materials like masonry, wood, and gypsum.

Now, strawbale construction is making a comeback as people are looking for more sustainable and environmentally-friendly building methods. The bales are made of tightly packed straw coated in plaster. It makes the structure fire-resistant and earthquake-proof.

The primary disadvantage is that it can be expensive to get the materials delivered to the site.

2. Rammed Earth

Rammed earth is a natural combination of soil, gravel, and sand that has been used for millennia. The ingredients are mixed and then compressed into blocks or panels using a mechanical rammer.

The earth blocks are durable, with a high thermal mass that helps to keep structures cool in the summer and warm in the winter. Rammed earth is also resistant to fire and earthquakes.

The main disadvantage of rammed earth construction is that it can be labor-intensive, requiring a high degree of skill to get the mixture right and use the rammer effectively.

3. Timbercrete:

It is a new type of construction material made from timber and concrete. The two materials are combined in a mixer to create a slurry, then poured into forms and left to set.

Timbercrete has all the advantages of both timber and concrete: it’s strong, durable, and fire-resistant, and it’s a good insulator, making it ideal for use in buildings and construction.

One main advantage is that it’s a natural product. The timber used in the mix comes from sustainably managed forests, so it doesn’t contribute to climate change.

4. Insulated Concrete Forms:

A typical ICF is constructed of two sheets of expanded polystyrene (EPS) insulation with metal or plastic reinforcing grids sandwiched between them. The form is filled with concrete, which sets around the EPS to form a thermal break.

The main advantage of ICFs is that they provide excellent insulation. It makes them ideal for use in climates where there is a lot of temperature variation, both seasonally and from day to night.

ICFs are particularly resilient. They can readily support the weight of an entire floor, even if it’s made of glass. It makes them ideal for high-rise buildings and other structures where weight is a concern.

Bottom Line:

If you’re looking for a less-is-more option when it comes to driveway paving, you may be thinking about whether there are any lighter alternatives to concrete. Fortunately, Straight Edge Contractors LLC, serving Las Cruces, NM, provides asphalt repair and seal coating services that can rejuvenate your driveway without the additional weight of concrete. So, what are you waiting for?

Asphalt driveways and parking lots endure a lot of wear and tear. Sooner or later, most of them will need some repair work. If you’re lucky, the only thing that needs fixing is a crack or two. But more often than not, entire sections will have to be patched up or replaced altogether.

Straight Edge Contractors LLC will discuss standard asphalt repair techniques to prevent your asphalt from turning into a money pit.

Patching – The Most Common Asphalt Repair:

What crosses your mind when encountering a crack or a hole in your asphalt? If you said, “I need to patch that up,” you’re on the right track! Patching is the most common form of asphalt repair. All you need is some cold patch (a pre-mixed asphalt found at most hardware stores), a trowel, and a little bit of elbow grease.

Once you’ve filled the crack or hole to the top, use the trowel to level off the cold patch. Then, give the area a few days to cure (dry). Once it’s cured, you can go over the area with a seal coat to give your asphalt an extra layer of protection.

Asphalt Removal and Replacement – The “Nuclear” Option.

If your asphalt is too damaged for patching or seal coating, you’ll have to replace it. It’s also known as peel and pave; paving repair and replacement is a more comprehensive and long-term answer than surface patching. This technique is highly efficient in preventing and repairing reflexive cracking. It will necessitate the assistance of an expert asphalt contractor.

Reflective cracking is a form of damage that occurs due to repeated stress concentration in a particular asphalt area (for example, heavy vehicles constantly driving over the exact location). The continual pressure will cause the overlay to crack with time. The objective of peel and pave to keep as much of the original asphalt pavement as feasible so that it may be blended into a new and stronger aggregate.

Milling – The Last Resort:

Milling is a process whereby a large machine grinds down the top layer of asphalt. It is usually done when the asphalt has reached the end of its lifespan and can no longer be repaired.

This method is usually a last resort for two reasons. First, milling is very disruptive and creates a lot of dust. Second, it is expensive! That being said, there are some advantages to milling. For example, if the underlying asphalt is in good condition, milling can be used to level out a surface.

Full-Depth Repair – The ‘Solid’ Solution:

Full-depth asphalt repair entails superseding your complete pavement system. The procedure is commonly reserved for cases where the foundation or the stone base has been substantially damaged and needs to be repaired or replaced.

When the pavement base is damaged, it’s nearly impossible to repair it while it’s still in the ground. Instead, before replacing the asphalt aggregate on top of it, the entire foundation needs to be dug up, reformulated with a stronger aggregate, and then reapplied.

Conclusion:

Asphalt repair is one of those cases where it’s best to leave the work to the pros. Rest easy knowing that your asphalt repair will be done right when you contact a licensed contractor like Straight Edge Contractors LLC in El Paso, TX. Our experts can help you with all your asphalt repair and maintenance needs!

Whether paving a commercial or private parking lot, there are two main options: asphalt or concrete. Both have their benefits and drawbacks, making it difficult to decide which one is right for your business.

Straight Edge Contractors LLC compares asphalt parking lot vs. concrete parking lot to help you choose the right option for your Midland business.

The Pros of Asphalt Paving:

No. 1: Quick Installation, Lower Cost

Asphalt paving can be completed quickly, making it a great option if you need to get your parking lot up to and running as soon as possible. It’s also less expensive than concrete, making it a more affordable option for many businesses.

No. 2: Green Thumbs and Roads

We value asphalt for its environmental friendliness. Asphalt comes from recycled materials, so it doesn’t require burning fossil fuels as concrete does. You can even recycle old asphalt to create new asphalt pavement, further reducing its environmental impact.

No. 3: Long Lifespan

While it demands regular maintenance, asphalt can last you several years with proper care. Only the top layer is removed instead of the entire pavement when repaving, which saves you time and money.

The Cons of Asphalt Paving

There’s a bad apple at the bottom of every barrel, and asphalt is no exception.

- Hot Weather: An asphalt pavement will not stand summer temperatures of over 100 degrees Fahrenheit. Instead, it will start to melt, and the tar will run off the sides of the road.

- Maintenance: Asphalt requires attention and frequent repairs and sealants every few years to preserve its color and protect it from the weather.

The Pros of Concrete Paving

Now for the good news! Concrete is an excellent choice for paving parking lots because:

No. 1: Durability

Concrete paving can last for numerous years without needing repairs or replacement. Your concrete pavement might even outlast the asphalt around it. When concrete does crack, the cracks are usually small and easily repaired.

No. 2: Beat the Heat

Concrete is much more heat resistant than asphalt, so if you live in an area with long, hot summers, concrete is excellent for your parking lot.

No. 3: Design Options

Not only is concrete paving aesthetic, but it can also be stamped or stained to create a more customized look. You can even add color if you want! Add some dimension and style to your parking lot with concrete.

The Cons of Concrete Paving

Nothing is perfect, and concrete has a few drawbacks.

- Installation Time: As opposed to ready-set-go asphalt, concrete takes twice as long to install and even longer to cure.

- Water Drainage: While porous or permeable asphalt allows water to drain into the soil, concrete does not. This can lead to water pooling, which is an eyesore and a potential safety hazard.

- Winter Blues: Asphalt holds up pretty well in the winter, but concrete is susceptible to freeze or thaw expansion and contraction cycles that can cause cracking.

Conclusion

Looking for a reliable paving contractor in Midland, TX? Look no further than Straight Edge Contractors LLC. We provide quality paving solutions at competitive prices, and we’re always here to answer any questions you may have.

If you’ve got faded line striping on your parking lot, don’t worry – help is here! This blog post will discuss some methods for removing those pesky markings.

And if you’re looking for a reliable contractor who can take care of the job for you, be sure to contact Straight Edge Contractors LLC. We offer high-quality asphalt paving services and associated services that will have your lot looking good as new in no time!

Method 1: Scarifier

Have you ever heard of this fancy machine? A scarifier is a type of milling machine that’s often used to remove paint or pavement markings. It works by scratching the top layer of asphalt off your parking lot surface.

By “scaring” off the striping, you’ll be left with a surface that’s ready to be repainted or re-striped.

This is a more aggressive approach, so it should only be used as a last resort. If you’re unfamiliar with handling a scarifier or don’t have access to one, it’s best to leave this job to the professionals.

However, it is thorough and will remove all traces of faded stripes from your parking lot.

Method 2: Shot Blasting

No, it’s not the same thing as sandblasting. Shot blasting uses small “shots” made of either metallic materials or gentler abrasives like organic media or glass to resurface your pavement.

This method is also effective but can be pretty loud and messy. It’s also important to note that a professional with the proper equipment should only do shot blasting.

It takes concentration and time, both of which you may not be able to offer. However, once it’s done, your parking lot will look as good as new!

Method 3: Water Blasting

Not to be confused with pressure washing, water blasting uses high-pressure water jets to remove faded stripes from your pavement.

This method is effective but can also be messy. It’s essential to have the proper equipment and training to execute this method correctly, as it can be dangerous if not done properly.

Once again, we recommend calling a professional rather than attempting this yourself. Water blasting leaves a good finish with little to no damage but can be expensive.

Method 4: Soda Blasting

Baking soda is an excellent medium for stripping paint and other finishes from surfaces. It is also non-toxic, making it a safe choice for removing faded stripes from your parking lot.

Soda blasting is similar to sandblasting, but baking soda instead of sand. The stuff blasts off the old paint and leaves the surface clean and ready for new stripes.

Not only that, but it leaves little to no mess and is a relatively cheap option.

If you’re looking to remove faded stripes from your parking lot, we recommend soda blasting. It’s safe, affordable, and leaves little mess.

Conclusion

Are you facing challenges with your old parking lot striping? No worries! The experts at Straight Edge Contractors LLC are here to help.

We offer reliable and professional services in Las Cruces, NM, that will get your parking lot looking like new in no time.

Take a long, hard look at your driveway or parking lot, and decide whether it’s acceptable to neglect the graying asphalt, get it repaved, or take the rejuvenate & seal coat step?

Straight Edge Contractors suggest repaving as the consequential norm for pavement that can’t be recovered due to years of pavement distresses like ruts, cracks, slippage, & potholes. But where your asphalt is just a bit cracked and gray, you can take the seal coat route to revive your surfaces!

Sealcoating: A Review

It is a class of surface protectants & treatments, usually exclusive to asphalt pavement, involving bituminous material emulsified in an aqueous solution. The liquid is heated & dispensed over pavement, allowed to cure, and then it protects the asphalt from oxidation & pavement failure.

Application Essentials

- Spray or squeegee are the two most common techniques for applying sealer.

- You need clean, oil-free asphalt surfaces for the coat to adsorb onto the pavement.

- Humid or cold weather does not favor seal coats or emulsions. Care should be taken to restrict seal coats to stable summer months.

- Keep an eye out for rain or sources of humidity that can interfere with the coat’s adhesion to the pavement.

- To ensure a successful seal coating, the air and pavement temperatures should be at least 55°F for the duration of the application and for eight hours after it is completed.

Facts & Benefits!

- Asphalt pavement is almost indestructible, thanks to the seal coat that fills surface damage and gives a protective barrier against eroding UV rays, vehicle fluids, and water.

- A regular coating on your asphalt driveway can save you money in the long run. A properly cared for and sealed asphalt pavement has a longer lifespan and reduces future repair expenses.

- As the asphalt pavement is exposed to the elements, it becomes worn over time. Asphalt looks and feels like new after a fresh seal coat application.

- Sealing the pavement with epoxy sealer hastens roadways’ snow and ice melting process. This helps prevent water intrusion, rain, frost, and snow damage.

- Among seal coats, the emulsions emerged as a protective coating that can work to some degree at colder temperatures above freezing.

The Cost-Effective Part?

Essentially, when your asphalt pavement, parking lot, driveway, or even an outdoor sports court are protected by a variant of a seal coat, that means curb erosion & pavement longevity. That means fewer repair intervals, though you have to remain regular on annual maintenance.

The longer your parking lot pavement maintains a blacktop, the more attractive it is to visitors with business in the surrounding areas.

A seal coat helps you gain maintenance & repair savings because the asphalt is protected from reactive damage from the weather & vehicles. If you want to keep your asphalt surfaces performing optimally, you better sign up with us, Straight Edge Contractors, for repairs, drainage design, ADA compliance & much more.

Check our services offered in El Paso, TX. The weather is ripe for a coat so get in touch for free quotes today!

Edging asphalt is about more than aesthetics; it makes it more robust and blocks weeds. The most effective weed prevention method would be to lay down geotextile fabric under your blacktop pad. However, if this isn’t in the budget right now, the next best thing is to edge your asphalt with straight edge tools regularly. Straight Edge Contractors LLC will highlight the importance of edging your asphalt in this blog post.

1. Edging Your Asphalt Makes It Stronger

A significant benefit of having well-edged asphalt is that it makes it much more substantial than un-edged asphalt. If you fail to edge your asphalt regularly, then over time, there will be significant cracking throughout the pavement, which leads to considerable damage later on down the line when you’ll need to tear up and replace large sections of asphalt at a time. Not to mention the ruts and craters that will start to appear, which make it difficult for drivers to navigate across safely.

2. Aesthetics Matter

Looks aren’t everything, but they do matter. The last thing you want is an un-edged asphalt driveway because, over time, it’s going to look worn and weathered and just downright crappy. It happens with edged blacktop as well, but not nearly as fast as un-edged asphalt, making it much more aesthetically pleasing if you’re looking to sell your property down the line—especially if you have gravel borders!

3. Edging Your Asphalt Will Make It Durable

There are lots of things that impact how long your asphalt will last without maintenance, but one of the most significant contributors is if it’s edged or not. Think about it this way – How long would a rug last in your living room if you never vacuumed underneath it? Probably not very long because over time, dust and dirt will accumulate there, and you’ll end up with a filthy-looking carpet that needs to be replaced.

4. It Keeps Your Pavement Easier To Maintain

Edging asphalt keeps weeds from taking root in the cracks between paving stones and makes cleaning and maintenance easier because debris can’t get trapped inside where you can’t reach it.

Whether you’re doing the edging or calling in a professional landscaping company to do it for you, use straight edge tools to keep your asphalt looking great, and everyone will appreciate the effort!

If you have any outdoor area on your property—from a driveway around your house to garden pathways or part of your backyard—you might want to consider making sure that the edges are as clean and clear as possible. The reason this matters is because, over time, grass and other vegetative plants will begin to infringe on your asphalt, making scruffy-looking edges. Grass grows very quickly and can force its way into cracks in the asphalt, while weeds grow up through the pavement itself.

Straight Edge Contractors LLC can help with your asphalt repairs in Midland, TX! You have to provide us with some information about your project to get a free estimate now!

When building a retaining wall, the foundation is one of the essential parts. The wrong material can lead to your wall collapsing, so it’s necessary to choose the right one. You can use several materials for a retaining wall foundation, but we at Straight Edge Contractors LLC will highlight the two main material choices here.

Why is a Retaining Wall Necessary?

Retaining walls are usually built to protect an area from soil erosion, runoff, or landslides. They also help prevent flooding, which is often one of the most common reasons homeowners invest in retaining walls.

Types of Retaining Walls:

Before choosing a retaining wall foundation, you need to consider what type of wall you want. There are different retaining walls, and the one that will work for your property needs to be selected carefully. Some examples of common types include:

Gravity Retaining Wall: This type of wall relies on the natural force of gravity to keep it in place. It’s usually made from a stack of large, flat stones and is one of the most common types of retaining walls.

Cantilevered Retaining Wall: This type of wall is anchored into the ground at only one end. The other end hangs over like a ledge, which gives it its name.

Counterfort Retaining Wall: This type of wall uses an opposing pair of walls (known as counterforts) to hold it in place. The counterforts are typically short and stout, while the main retaining wall is longer.

Asphalt vs. Concrete Surfaces for Retainer Walls

Asphalt pavement is a preferred choice for parking lots and driveways over concrete. With regular care, it’s long-lasting and straightforward to maintain. However, the fill depth beneath an asphalt surface differs from concrete. Concrete surfaces are often topped with a deeper, more solid foundation. It makes concrete more durable and less susceptible to movement and damage from frost heave.

There is a big difference in the hardness of the two surfaces and terms of flexibility. Because the asphalt has some flex in it, placing something hefty on top of it without a solid foundation might become an issue.

The weight of the wall could cause the asphalt to crack or settle, which would harm the wall over time.

In contrast, a concrete surface is much more rigid and can handle more weight. If you have a retaining wall that will be very heavy, the best choice is to use a concrete foundation.

Choosing the Right Material:

When building a retaining wall, the type of material used for the foundation is critical to the project’s overall success. If you’re unsure which material is suitable for your situation, consult with a professional before getting started. They can assist you in choosing the best foundation for your specific needs and ensure that your retaining wall will be safe and durable.

Straight Edge Contractor LLC offers a variety of solutions for your construction projects in Las Cruces. You can reach out to our team to help you choose the suitable material for your next project. Schedule your free estimate!