Sealcoating protects pavement from the elements by creating a protective barrier over the surface. Sealcoating is usually done every two to three years to keep your sealcoat in good condition.

While sealcoating is a simple process, it is crucial to take the time to do it correctly for the best result. There are sealcoating mistakes that can be made, which will make your sealcoated driveway look aged and worn very quickly. However, some of these mistakes will only be evident later!

This article will go over sealcoating mistakes that many property owners make without realizing until their sealer has already dried.

Not Ensuring that the Sealant is Applied Evenly

This will lead to the sealant wearing off unevenly where it is thicker or thinner, which can cause problems in future years. For example, if there were spots that weren’t sealed well during sealcoating, water would have a place to pool up and get underneath your driveway’s sealant. This can cause cracking, splitting, or even creating a pothole in the sealant over time where water has pooled up underneath it.

Applying Only One Coat of Sealant Instead of Two

Another sealcoating mistake is not applying a second coat of sealant after the first one has dried. If this step is skipped, water and other elements will get underneath your sealcoat over time which causes damage and wear down. For best results, make sure you apply two coats of sealer instead of just one.

Not Purchasing the Right Sealant

When sealcoating your driveway, you must use a suitable sealant. Using a low-quality sealer will not last as long and is more likely to make your surface vulnerable to damage. Make sure when sealcoating your driveway you purchase high quality sealer with all-weather capabilities. Make sure to buy a sealer that matches the type of surface you are dealing with because certain sealers are not meant for concrete surfaces and will damage them over time.

Not Waiting for the Right Weather

Make sure to sealcoat your driveway or parking lot during the warmer months when the asphalt is soft and pliable. If a sealcoat is applied to cold asphalt or concrete, the sealer will not cure correctly and leave stains on your surface that are hard to remove later on. The ideal temperature for sealcoating is 50+ degrees, and if the sealer is applied at temperatures under 50 degrees, the sealcoat will not adhere to your surface well.

With a bit of help from Straight Edge Contractors in Las Cruces, NM, you can avoid the paving and sealcoating mistakes that keep property owners up at night. Get your free estimate today and see how our asphalt paving and sealcoating services can save you time and money by sealing your driveway the right way, the first time!

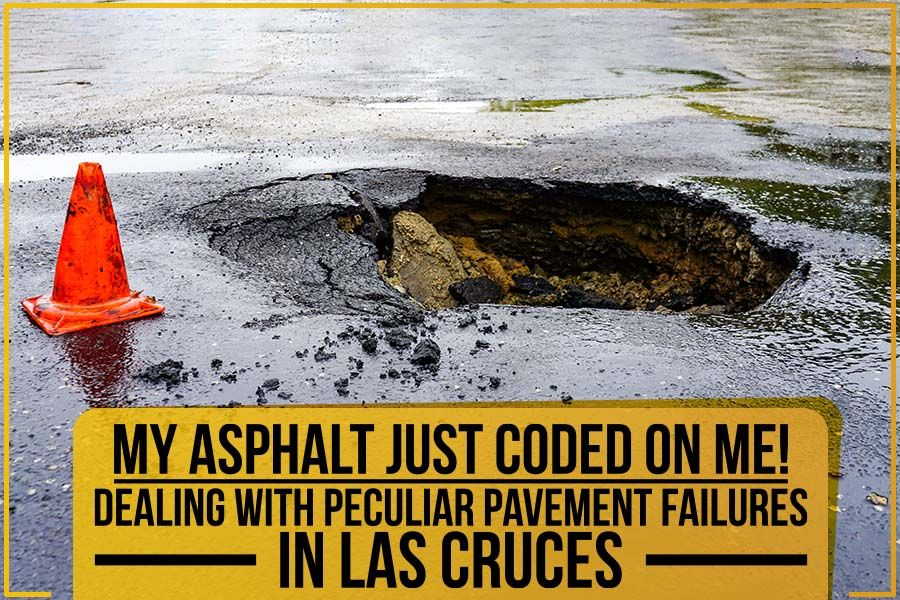

What may seem like a mere ‘crack’ to you is probably a cascading category of asphalt damage to an expert. It could be the surface, or a layer is missing, or the base is bad. Iterations keep running through a contractor’s head to arrive at the right way to deal with the damage so that it does not resurface again. So, an amateur going out on surface knowledge is bound to embarrass themselves before the experience and eye of a professional paving contractor, just like ours at Straight Edge!

We’ve come across many an odd pavement failure that we feel obligated to share with you since our absolute joy is helping clients develop an eye for things, too!

1. Block Cracks:

These cracks make the pavement look like it was cracked into rectangular sections. The cause is due to shrinkage of the asphalt because the poor-quality binder layer could not adapt to fluctuating temperature cycles. Dry and old asphalt will exhibit this cracking too. Small cracks require a sealant to guard against water intrusion, but extensive damages may require asphalt removal and overlay in the affected sections.

2. Flushing:

This is a hazardous issue, especially in winters or wet roads. With excess use of asphalt binder, the aggregate gets saturated like a sponge, especially if the aggregate was too finely blended. This is a design error in aggregate preparation. So, when heavy traffic resumes in ideal hot paving weather, the load compacts the asphalt and flushes out the binder to the surface like a shiny, oily film. The process is irreversible in winters and causes a lack of traction and becomes accident-prone. Minor flushing can be blotted out by applying sand, but in worse cases, the affected section is milled to remove excess asphalt or graded using heater planers.

3. Joint reflection:

This happens when a rigid slabbed pavement base is paved with a flexible layer. The most obvious case is paving asphalt over a concrete base. Rigid pavement has a more pronounced reaction to temperature cycles compared to flexible. Since concrete is paved in slabs, the point where the slabs join is where the overlaying asphalt cracks due to the underlying deformation processes. Small cracks are easily sealed, but cracks too deep to be filled require removal, replacement of slab, and an asphalt overlay.

4. Slippage Cracks:

These ‘cracks’ look more like loose elephant skin where the asphalt has slipped over the sub-base. This fault can occur when paving contractors don’t apply a tack coat to bond the asphalt layers. Or they skip out on a prime coat to bind the asphalt layers to the sub-base. Or oil and dirt are preventing the adherence of the asphalt to the subbase; the loose elephant skin is the result. Any section displaying this ‘loose skin’ requires a partial or a full-depth repair.

5. Wash-board Distress:

This type of odd failure makes the pavement look like it has ripples across its surface. It is common at road sections that experience extreme stress, like pavement intersections. It happens if the asphalt aggregate was too finely blended, which makes the asphalt soft, and forms a weak base. The only way to fix this is a full-depth asphalt repair.

Being a paving contractor is not just bragging about asphalt and compactors in a baritone at your local brewery after a job well done and a client left in awe. Contractors study to bend asphalt to their wills, and as is with all arts, it takes time and practice to have an eye for things. At Straight Edge Contractors, we market our level of experience and base our services on it so you may get the best deal out of our free estimates. We are active in the sun and rain of Las Cruces, New Mexico, so if you require our honed services, we are nearby and geared up to flatten the faults in your asphalt!

Let’s begin with an introductory science lesson; water expands when the temperature goes down to 39F and becomes ice. This causes the water particles to take up more space between them and behave differently from the hydrating properties of liquid water. Concrete is bound by water-based cement and requires liquid water to activate its chemical cementing properties until it reaches a particular compressive strength, after which nothing can compromise its setting. However, this can take a while in colder temperatures, plus lead to crumbly concrete if the temperatures caused it to freeze.

In El Paso and across Texas, the winter temperatures can reach 32F and below with cold winds that don’t make ideal conditions for both fresh asphalt and concrete. But some emergencies may call for a pouring or overlay job in the cold season. There are specific tweaks that can work to your advantage in such conditions, and we will list out a couple to help you understand why.

It helps to know these tricks when you are a concrete pouring contractor or even a DIY property owner who wants a few quick additions to spruce up the property like a jack of all trades!

- Use hot water in preparing your concrete mix. 65F is a suitable temperature for mixing with consideration to the thickness of the concrete mix.

- Ensure a wet concrete mix of a measured consistency and fluidity for winters, and have it pumped out through an air-entraining system. Air entrainment adds bubbles to the concrete mix that provides stress relief and resistance to frozen or thaw conditions upon solidification.

- Calcium chloride, a type of salt that is very friendly with water, is used as an accelerator in concrete during cold weather. The calcium chloride speeds up the hydration reaction when mixed in as 2% of the whole concrete batch. However, care needs to be taken as this method is unsuitable for use in rebar concrete, as the calcium chloride in the concrete will corrode the steel over time. Just don’t think this is an anti-freeze solution; it’s just a way to speed up the concrete setting time in the cold and can go wrong!

- All fresh concrete ‘bleeds’. This is the process where the poured concrete expels excess water to its surface, and it needs to evaporate. In winters, this is difficult if the bleed water freezes. It is a hassle, but using sponges and wet vacuums can ensure suitable surface drying for further leveling.

- Avoid fly ash or water reducers in cold weather concrete. It will only make the conditions worse for settling the concrete.

- Once the concrete is poured and leveled, it’s time to get an entire baby care kit set up for the next 48 hours to ensure the concrete will cure properly. You will need insulation blankets that keep the temperatures up to 50F. You can also use containment units placed over the poured sections with a ventilated heater.

If you’ve kept these points in mind, you can easily avoid most mistakes people make with cold-weather concrete pouring. At Straight Edge Contractors, we know best the amount of blankie-love your new concrete needs. While the weather in El Paso is ideal for conventional concrete paving, if ever needed, you can rely on our residential and commercial services come winters too! If you desire a consultation, check our free estimates, and you sure won’t be disappointed!

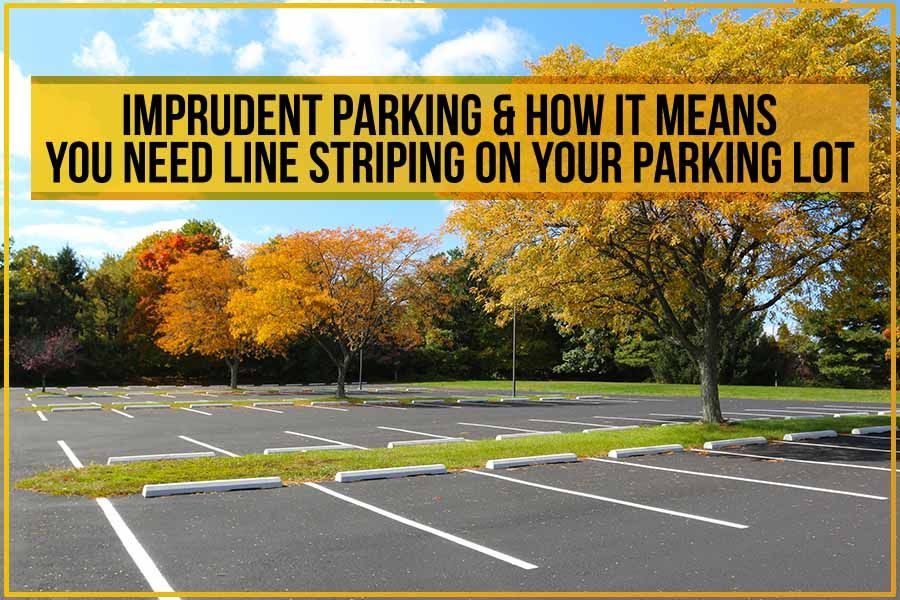

Making your way downtown, driving fast, faces pass, and suddenly you’re parking-lot-bound. The lots are busy, the asphalt cracked, the parking lot line striping is faint, there are potential bad drivers pulling up and parking haphazardly. You try to reverse and miss a worn-out warning at the turn, and voila! – a fender-bender to further ruin a grocery run on a swelteringly hot day.

To avoid parking mishaps, you need expert parking lot maintenance companies to stripe and re-stripe parking lots. You’ve seen it in the movies: a steady background of cars parking all nice and neat on a well-maintained parking lot. Lines keep people in line!

Here are some solid reasons when and why you need to line stripe and re-stripe every couple of years if you want your parking lot to look neat and conflict-free!

1. Like Sardines in a Can

It’s easy to point at a badly parked cars and make a quip about the drivers being visually impaired, whereas it could be poorly panned lot lines that aren’t apparent enough as a marker to park correctly. Parking lot striping should be done in a manner that allows for the maximum utilization of space without cramming. There are striping formats that can be used to this end (straight, fishbone, angled, handicapped section).

2. Lines? What lines?

Line striping paints are usually water-based acrylics, formulated for brightness, durability, and ease of application by rollers and sprays. They are meant to be vibrant and visible without using thermoplastic reflective paints suited for asphalt and concrete roadways. If these lines are not visible, they present a parking hazard.

3. Parking Violators

Dull or eroded parking lot lines are the bane of a good Midlander. It won’t take long for a parking violator to spot the dull lines and squeeze in. Vehicles parked over the line give more parking space but can hinder the minimum distance to open your vehicle’s door and maximize denting your truck or your neighbor’s SUV.

4. ‘I’m sorry, officer, I’d no idea this was a handicapped spot!’

From the city that brought us the excellent acting skills of Tommy Lee Jones, do not pull the naive act on an officer when caught in a parking violation. Either you are aware and disregarding, or you’re – well – dense. If you see the handicapped spots too far abused as a parking lot owner, it’s time for a severe line striping makeover.

5. Fender-Bender Festival

If you find out that weekly fender-bender statistics are reaching double digits on your turf; time for parking lot line striping. When parking lines are not clear enough, or wholly eroded in places, damaged asphalt and all, accidents are bound to happen. Clear signage, arrows, light fixtures, good pavement, and lines are static modes of communication to guide parking lot traffic seamlessly; hence it needs to be visible without causing distraction.

If you believe that you are plagued by forces of lousy parking and faded lines in Midland, TX, we’re the folks to handle it! At Straight Edge Contractors, we offer a range of asphalt and concrete pavement solutions that include line striping. For a free estimate, drop in to share your details, and we will give you a good deal on how to exorcise those bad parkings away!

It’s no secret that paving projects can be challenging. Many factors can lead to the failure of projects, from the complex logistics of getting materials into remote areas to the ever-changing weather patterns. Seasoned contractors like Straight Edge Contractors can list various reasons behind a wrecked pavement project. This blog post will discuss some of these challenges and how they may affect your paving project.

1) High Costs of Wrong Estimates

Paving contractors must know how much material they require and the area to be paved to give you a precise and accurate estimate. If they do not know how much material is needed, they may haul more than the required quantity to the site, costing more money for materials left behind. This can also lead to an under-estimate where there isn’t enough area covered, which creates cracks, water infiltration, and even potholes after some time.

2) Absence of Quality Equipment

Having the right equipment available onsite is critical to getting things done faster and less waste for paving projects. Most paving projects require contractors to use high-quality equipment to ensure the quality of the pavement.

If a contractor is working in your area, make sure they have all their equipment ready to go before the start of the project! You can also ask for references from previous jobs so you can see how things look after installation and get an idea of what the results would look like if they were working on your property.

Having all the necessary items on the site keeps project costs down as contractors don’t need to make multiple trips back-and-forth between supplier locations or construction sites to get supplies.

3) Injuries and Legal Hassles

Paving projects are serious business, especially when it comes to excavation. There’s a lot of maneuvering equipment around the worksite which can lead to accidents if precautions aren’t taken. This is why all employees must have proper training and safety gear before starting work, so everyone stays safe! Workers’ compensation insurance helps protect employers against injuries on the job and helps avoid legal action from workers who are hurt while doing their job.

4) Mismanagement and Inexperience

Another reason paving projects fail is poor management or inexperience. The right people must be assigned to tasks for this process, especially when managing a large team of workers – everyone needs to know what they are responsible for! Also, make sure your contractor has experience in what he does and can provide references if needed! You don’t want someone inexperienced working on your project because it could lead to problems down the line. An experienced contractor is well-versed with the weather conditions, the environment, and the set procedures that need following. They also bring efficiency and professionalism to the table.

Straight Edge Contractors offers reliable paving solutions to property owners in El Paso, TX. We use our experience and equipment to provide a complete paving solution. Get your free estimate to get a stunning commercial or residential pavement.

Line striping is a line painting technique used for traffic control. It includes applying line-markings to a surface and clearly indicating lane boundaries. Line marking can also be applied at intersections to guide pedestrians. The main purpose of line striping is safety.

You may be wondering how much does line striping cost? Well, it all depends on your specific project needs. When calculating line striping costs, there are many things to consider, including location, the number of line stripes needed, length of time, etc.

Let’s discuss these considerations in detail to understand what goes into a line striping project.

Location

The location where you need to apply line stripes will play an essential role in determining the cost of your project because there are different types of striping products available for each environment (e.g., indoor vs. outdoor). When it comes to calculating your line striping project’s cost, there are many factors you should consider, such as:

- Whether line striping is for indoors or outdoors

- The surface of the line (e.g., solid or dotted line)

- The line striping’s color

And more!

Number of Line Stripes Needed

The cost of line stripe projects can vary depending on the number of lines in your project and their size. The size and length of the lines you want to stripe or mark on your surface determines the number of line stripes needed for a project.

With line striping, it is usually best to use a line width of 12 inches or more. If you use less than this amount, the lines may be too small and difficult for people to see. To determine the cost, here are a few things you will have to consider:

- line count

- number of lines needed for your project

- how many line stripes do you want to have in total?

- line width and height

- total line length

- line spacing between stripes

Length of Time

Longer line striping projects require more time and effort, which also means they cost more. If you have a line striping request with an urgent deadline, it will cost more than a project with no urgency.

New Line Striping or Restriping?

You may hear line striping contractors ask you if you want new line striping or restriping because brand new line striping can cost up to three times more than simply restriping the same lines on an existing parking lot. This price difference is due to the equipment used and how long ago the parking lot was line striped.

Line striping is an essential part of any parking lot maintenance plan. It helps make your facility more safe, visible, and accessible for drivers in the area. Straight Edge Contractors LLC is here to help you with all your line striping needs. We are the go-to contractor for parking lot and traffic lane striping, as well as other asphalt services.

If your business requires line striping service, we would be happy to help. Give us a call today so we can schedule an appointment. Straight Edge Contractors LLC is here for all your asphalt paving, repair, and line-restriping requirements in Midland, TX.

5 Signs Your Asphalt Pavement Needs Repair

1. Cracks in the Surface

A crack is a sign of fatigue in asphalt and may indicate that asphalt has been significantly overworked by traffic. Cracks need to be fixed quickly before they get bigger and potentially lead to potholes.

Cracks result from soil expansion or shrinkage, shifts in grade, frost heave, or other natural occurrences that may cause asphalt to crack. An asphalt paving contractor will need to come out and assess the condition of your asphalt before deciding what kind of repairs are needed.

2. Humps

Asphalt pavement is designed to have some room for expansion when water collects on the surface, but if you start noticing humps forming, this could mean that water isn’t draining away from the area quickly enough.

3. Bumpiness

This can be a sign that asphalt is worn down and needs to be resurfaced. You can tell asphalt is worn down when the asphalt has lost its “bounce.” It should be repaired ASAP to prevent it from getting worse and causing costly damage.

4. Potholes

One of the most obvious signs of asphalt wear and tear are potholes. They form on asphalt that has deteriorated and has lost its resilience, so it can’t withstand pressure from cars or other heavy loads.

5. Water Pooling

A water puddle on an asphalt surface typically means there are cracked or damaged areas where water has penetrated and pooled due to uneven slabs or joints.

When water seeps into asphalt it can leave behind moisture and debris in the cracks of the surface. Excess water can cause the surface to soften and eventually deteriorate, leaving the pavement no longer able to withstand vehicular traffic.

It is essential to address water pooling as soon as possible by contacting a professional asphalt contractor with expertise in asphalt repair.

The Final Word

While the top five signs your asphalt pavement needs repair may not all be easy to spot, addressing them is crucial for your property. If you’re unsure what to do, connect with us at Straight Edge Contractors LLC.

Our experts are skilled in repairing all kinds of asphalt damage using high-quality materials, equipment, and advanced techniques to restore your surface to its pristine condition. We do this and more, all while keeping your budget in mind too!

We want all businesses in Las Cruces suffering from aging or damaged asphalt surfaces to get back up and running without delay. We believe asphalt repair is an investment in convenience, safety, and curb appeal! Give us a call today so we can schedule an appointment.

Asphalt is one of the most common types of paving materials used in construction. It is valued for its durability, low cost, and ease of installation. However, asphalt pavement can deteriorate over time due to several factors, including age, traffic volume, environmental conditions (such as temperature), and other external forces.

The best way to know if your asphalt pavement requires repair is by looking out for these five signs.

1. Cracks in the Surface

A crack is a sign of fatigue in asphalt and may indicate that asphalt has been significantly overworked by traffic. Cracks need to be fixed quickly before they get bigger and potentially lead to potholes.

Cracks result from soil expansion or shrinkage, shifts in grade, frost heave, or other natural occurrences that may cause asphalt to crack. An asphalt paving contractor will need to come out and assess the condition of your asphalt before deciding what kind of repairs are needed.

2. Humps

Asphalt pavement is designed to have some room for expansion when water collects on the surface, but if you start noticing humps forming, this could mean that water isn’t draining away from the area quickly enough.

3. Bumpiness

This can be a sign that asphalt is worn down and needs to be resurfaced. You can tell asphalt is worn down when the asphalt has lost its “bounce.” It should be repaired ASAP to prevent it from getting worse and causing costly damage.

4. Potholes

One of the most obvious signs of asphalt wear and tear are potholes. They form on asphalt that has deteriorated and has lost its resilience, so it can’t withstand pressure from cars or other heavy loads.

5. Water Pooling

A water puddle on an asphalt surface typically means there are cracked or damaged areas where water has penetrated and pooled due to uneven slabs or joints.

When water seeps into asphalt it can leave behind moisture and debris in the cracks of the surface. Excess water can cause the surface to soften and eventually deteriorate, leaving the pavement no longer able to withstand vehicular traffic.

It is essential to address water pooling as soon as possible by contacting a professional asphalt contractor with expertise in asphalt repair.

The Final Word

While the top five signs your asphalt pavement needs repair may not all be easy to spot, addressing them is crucial for your property. If you’re unsure what to do, connect with us at Straight Edge Contractors LLC.

Our experts are skilled in repairing all kinds of asphalt damage using high-quality materials, equipment, and advanced techniques to restore your surface to its pristine condition. We do this and more, all while keeping your budget in mind too!

We want all businesses in Las Cruces suffering from aging or damaged asphalt surfaces to get back up and running without delay. We believe asphalt repair is an investment in convenience, safety, and curb appeal! Give us a call today so we can schedule an appointment.

The concrete curb and gutter are a vital part of any home’s exterior. Just like other materials, concrete does not last forever. So, you will need to regularly maintain it over time to continue enjoying its benefits for years to come. We all know that maintaining a property can be expensive, but it is worth the expense. Hire a professional contractor like Straight Edge Contractors LLC in El Paso, TX, for regular maintenance of your property.

The four benefits listed below will help you understand the importance of maintaining your concrete curb and gutter. If you’re the owner of a home with a concrete curb and gutter, then this blog post is for you!

1. Helps Prevent Erosion

Concrete is a naturally water-resistant material. However, without regular maintenance, it will wear down and become prone to erosion. Erosion can lead to significant structural damage like cracks in the concrete or even complete collapse of your curb! The best way to prevent this issue? Keep up with regular maintenance of your concrete curb and gutter. You can also install an anti-erosion membrane on top of your existing surface for additional protection.

2. Discourages Drivers from Sidewalk Parking

The problem with sidewalk parking is that it’s an inconvenience for the pedestrians on the sidewalks. The best way to discourage drivers from using these areas is by adding concrete curbs and gutters. Additionally, concrete curb and gutters also help in providing the much-needed structural support to a pavement.

3. Adds Aesthetic Appeal

You can also use curb and gutter maintenance to make your property more aesthetically pleasing. If you don’t want any plants or flowers in front of your house, then a simple concrete curb will do the trick! With an attractive exterior design that complements the curves of your home’s architecture, you’ll have a beautifully landscaped yard while still maintaining curb appeal.

4. Promotes Efficient Drainage

Curb and gutter maintenance promote an efficient drainage mechanism by helping water flow away from the building or down a storm drain. Not maintaining drains may result in repairs as debris and leaves may accumulate, resulting in slow drainage and high groundwater levels, especially during the rainy season.

You may not think of curb and gutter maintenance when you’re thinking about all the necessary activities to keep your property in good condition, but as you can see from the list above, it’s an essential part of the overall maintenance plan!

If you reside in El Paso, TX, you can always call on the professionals at Straight Edge Contractors LLC for reliable concrete maintenance. We provide complete maintenance and repair services, ensuring that your property gets the look it deserves. Feel free to share all your pavement problems with us and enjoy exemplary services at affordable rates. Get a free estimate now!

What is crack sealing? Crack sealing is an asphalt repair technique that involves applying a sealant to cracks in the pavement. The crack sealant creates a strong bond between the asphalt and any moisture present, which helps prevent moisture from seeping into the ground below. While crack seals are not as effective as full-depth repairs for larger cracks, they do help to make your parking lot safer by eliminating potential tripping hazards.

This blog post explains five things that many property owners may not know about crack sealing.

1. Crack sealing is a time-tested fix which is considered the most cost-effective preventive maintenance method as it prevents water from seeping through the cracks and eroding the base of the pavement, causing further asphalt deterioration.

2. The best time to perform crack sealing is in the spring or fall. Your asphalt pavement expands and contracts with temperature fluctuations, so sealing cracks during these times of year is more effective because it’s when they’re halfway between their minimum and maximum movement.

3. Most property owners don’t realize that it is necessary to prepare the crack before sealing for a more lasting repair. In fact, crack preparation can increase the longevity of the seal by 40%. There are two ways crack preparation is done. The first is the routing or saw cutting preparation method that involves creating a reservoir, so there is enough room for the sealant to adhere to the crack’s sides. The other method calls for using a blower or compressor to blow out any dirt and debris from the crack before the sealant is applied.

4. Over-applying the crack sealant is a common mistake that can be avoided by using a disc on the equipment or having the contracting team follow up with squeegees to ensure the sealant lies tight against surfaces. This is important before resurfacing because hot mix asphalt will melt the excess sealant, creating bumps on the pavement as it cools down. A roller coming along can cause machinery to slip if there’s more melted sealant beneath it than necessary.

5. You may be surprised to learn that crack sealing cannot be used to repair all kinds of cracks. For example, alligator cracks require resurfacing, patching, or repaving; a simple sealant fix cannot hold for long. There are various types of cracks that can be found on an asphalt pavement with varying extents of damage and causes. Thus, in order to determine if crack sealing is the right option for you, you first need to identify the type of crack marring your surface, and for this it is always best to consult the experts!

Finally, crack sealing is a simple process that can save you money and help protect your property for years to come. If you reside in El Paso, TX, don’t risk cracking up your investment! Get in touch with Straight Edge Contractors today to get a free estimate for crack sealing your driveway or parking lot.